After lacing the motor into the

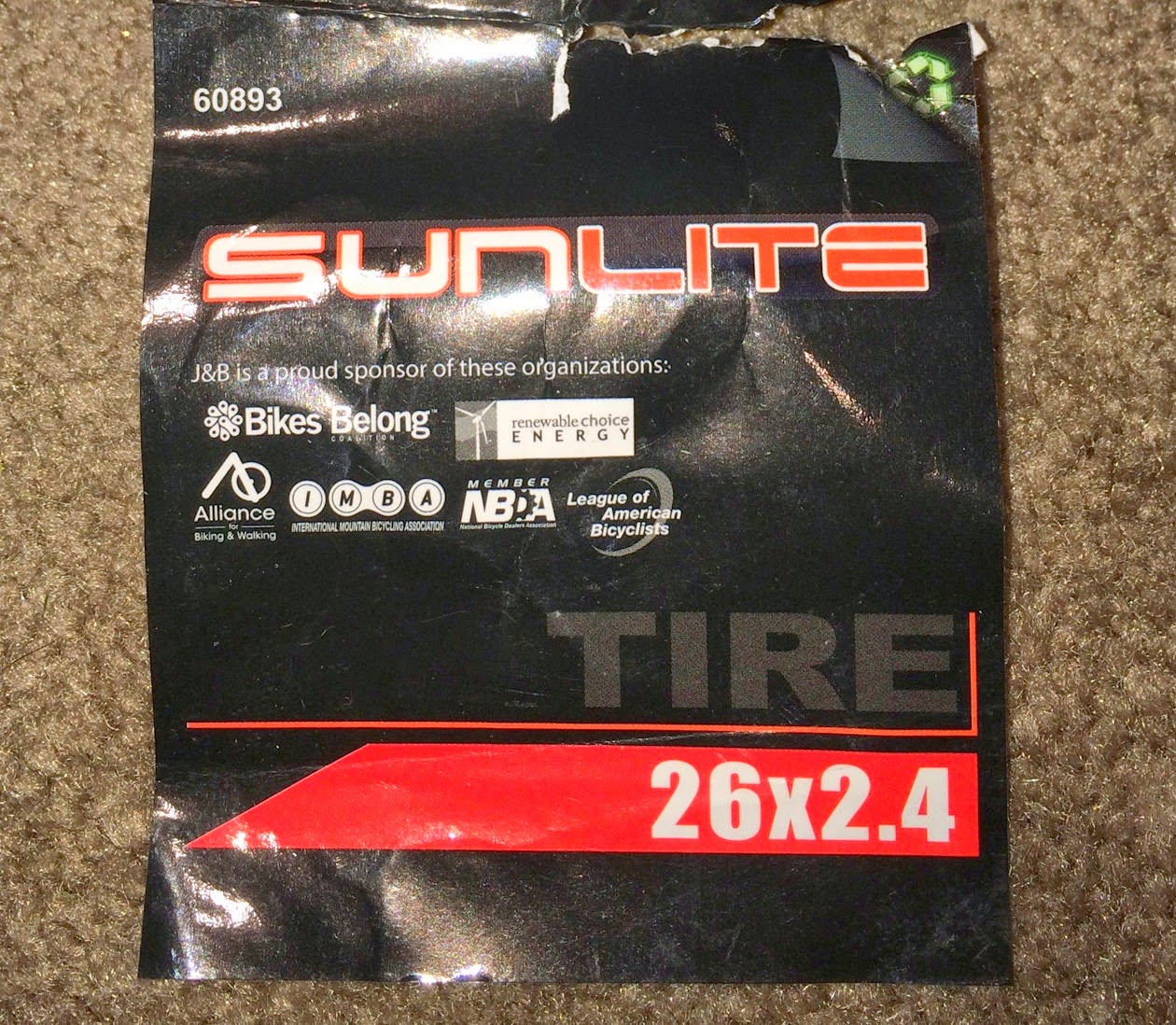

Alexrim wheel, I thought I'd just continue and finish up installing the motor into a Tidalforce frame and completing the bike! Presenting a newly assembled Tidalforce iO Step-through from various leftover and new parts. I plan on taking this to the office and getting some rides in during the day. The rear tire is a new Sunlite 26"x2.4" Schwalbe Big Apple clone. That's the Schwalbe Big Apple on the front wheel for comparison. You can see that the Sunlite does not have the nice reflective ring painted on the wheel. I eventually replaced the disc front wheel with a cheap rim brake wheel that I picked off a neighborhood kids bike that was about to be thrown away.

Profile:

Angle:

Rear triangle

Console with stylish keys

Rear triangle before the Cycle Analyst goes on

Folding pedals and double kick stand

The label from the new tire

After the Cycle Analyst goes on and the cheap wheel goes up front

Rear triangle with Cycle Analyst

Close up of the Cycle Analyst Standalone shunt in place

Cycle Analyst V2.23 mounted on bike handlebar

Wire cluster behind the Cycle Analyst